Norton

Norton 6000DMY Dummy Operator | Norton 6000 Series Frame Mounted Electrohydraulic Operator | Low Energy Operator

Don't see the quantity, finish, or function you are looking for? We can mix, match and "BUILD" the item option set you are looking for - Just call us at 860-537-1328 and our sales staff will assist !

Norton 6000DMY Dummy Operator | Norton 6000 Series Frame Mounted Electrohydraulic Operator | Low Energy Operator

The 6000 Series WiFi-enabled low energy operator is a heavy-duty unit designed for rigorous, high-use applications. Built-in intelligence enables the operator to safeguard users while providing better door control. Simple installation, setup, and adjustment, allows for seamless integration with a multitude of facilities and systems.

FEATURES

• Push or pull side mounting

• Non-handed

• Modular design for one person install

• LCD screen

• Full cover option on double/pair of doors

• 1.3A onboard power supply

• Activated by wall switch, hands-free, and RF devices

• Door width: 36"-48"

• Operates as a mechanical surface closer when power is off

• On board electronics collect usage and cycle count data to facilitate preventative maintenance/diagnostics

• WiFi Interface - No connection to building's WiFi is required

• NorGlide® fluid

FUNCTIONS

Adjustable Hold Open

– Amount of time a door will stay in the full open position after an activation

Blow open for smoke ventilation

– Door opens when signal is received from alarm system allowing air or smoke to flow through opening.

– Door will stay open until signal from alarm system is stopped

Infinite Hold Open

– Door will hold open at set position until power is turned off

Obstruction Detection

– Open: door closes if it hits an obstruction while opening

– Close: door reopens (once) if it hits an obstruction while closing. If it hits the obstruction again, the door will rest against the obstruction until it is removed

Open Delay

– Delays operator opening for locking hardware

Overload Safety Shut-Off

– After 3 minutes of receiving a door activation signal, inverter times out and door closes

– Prevents motor/inverter damage

Presence Detector Input

– Input for external sensor to detect presence at door open or close position only

Push & Go

– As the door is manually opened, the operator “senses” movement and opens door to the full-open position

Selector mode switch

– Off - Disables signal inputs unless Blow Open is activated

– On - Activates signal inputs

– Hold Open - Activates the unit (unless blow closed is activated on 6300) to the hold open position

Two Selectable Output relay

– Multi-function relay outputs

Vestibule Delay

– When the wall switch is pressed, first door in vestibule will open. Second door will open once vestibule door delay has expired. Delay is adjustable.

ELECTRICAL DATA

• Power input 120 VAC, 60 Hz (+10%, -15%)

• Current draw 0.9A (single), 1.8A (double)

• Auxiliary output 24 VDC @ 1.3A

• SPDT relay output for controlling electric strikes or electric locks not to exceed 1 amp @ 30 VDC

CERTIFICATIONS

• ANSI/BHMA A156.19 certified

• ETL tested to UL-cUL standards for automatic doors used on fire and smoke barrier doors and CSA C22.2 No. 247 for operators and systems of doors

• UL10C positive pressure push (3-hour), pull (90 min)

• Comply with requirements for the Americans with Disabilities Act (A.D.A)

• California State Fire Marshall Listing 3266-0944:0110

• Manufactured in an ISO 9001 and ISO 14001 facility

• Verified by Green Circle to offer the following energy savings as compared to similar products: – 19% efficiency

• Health product declaration and UL certified environmental product declaration

ARCHITECTURAL SPECIFICATIONS

• Door Controls (interior)(exterior) swinging door(s) shall be of rack and pinion design contained within a precision cast aluminum housing.

• Door closing force shall be adjustable to ensure adequate closing control.

• Door closing speed shall be controlled by independent hydraulic adjustment valves in the sweep and latch range of the closing cycle.

• Door Operator shall provide conventional door closer opening and closing forces unless the power operator motor is activated.

• Door Operator opening force and speed shall be adjustable in the inverter/interface module's LCD screen to ensure adequate opening control per accessibility codes.

• Door Operator shall have an adjustable hydraulic back-check valve to cushion the door speed if opened violently.

• Door Operator shall utilize the inverter/interface module's LCD screen and joystick to establish door closed and open positions. [(Door Operator shall be AUTOMATICALLY ACTIVATED by either a slight push or pull in the direction of opening swing – Push & Go.) (Door Operator shall be SELECTIVELY ACTIVATED by external initiating device, i.e. wall switch, etc.) (Door Operator shall be both AUTOMATICALLY ACTIVATED and SELECTIVELY ACTIVATED.)]

• Unit shall include “E-saver” feature to automatically recognize abled body traffic and immediately trigger door to close after sensing no forces on door.

• Unit shall have delay for motor activation, electric lock interfacing, and hold open time. Units shall have SPDT relay for interfacing latch retraction exit devices or similar products and have 24VDC @ 1.3A output for connection of electric strike, lock, radio frequency receiver, etc.

• Units shall have Vestibule sequencing input for operation of two or more units.

• Unit shall have smoke ventilation inputs to power open doors when activated by fire or smoke alarm.

• Unit shall have a three-position Selector Mode Switch that will permit the unit to be switched “ON” to monitor for function inputs, switched to “H/O” for indefinite hold open function or switched “OFF” which will disable function inputs allowing unit to be used as a manual door closer.

• Unit shall be ETL tested to UL standards for automatic closing door.

• The Unit shall be adjustable to provide compliance with the requirements of the Americans With Disabilities Act (ADA). Unit shall be certified by BHMA to meet ANSI A117.1 and A156.19 requirements.

• Unit shall meet UL10C, UL-cUL and UL10B standards

ADDITIONAL SPECIFICATIONS FOR FUNCTIONS

For Power Operator Function:

• When activated, the unit shall, by means of a motor, chain and closer, power open the door at both a speed and force that are adjustable to accessibility codes.

• The door shall be powered from a door closed position to a full door open position and remain in momentary hold open for 5 seconds minimum (adjustable 0 to 30 seconds in 1 second increments).

• [(Unit shall power open door to full open position up to 110°.) (Unit shall be capable of opening door manually from 110° – 180°.)]

• Once unit reaches full hold open position, if reinitiated, unit’s momentary hold open time shall restart from the maximum set time. If unit is initiated during the closing cycle, unit shall revert to opening cycle beginning at that door position.

• Unit shall have a toggled hold open input that upon first initiation will power door to a maintained hold open position; a second initiation will allow door to close.

• Unit shall have obstruction detection on closing, which will reverse the closing door to the full open position then re-attempt to close door after momentary hold open time has elapsed.

• Obstruction detection on opening shall shut motor off, allowing door to close under spring force. These obstruction detection features shall be integral to unit. During closing cycle, the unit shall close door under full spring power not to exceed a closing force of 15 lbf.

APPLICATIONS

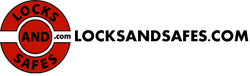

Norton 6011 Operator

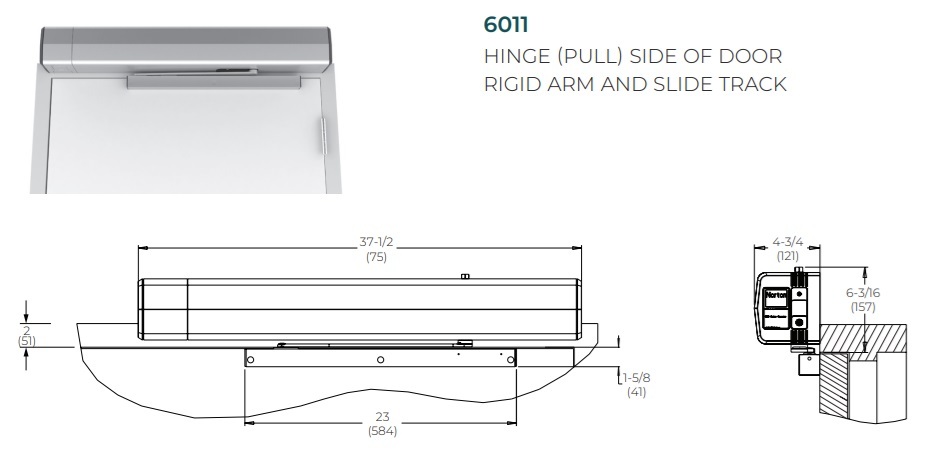

Norton 6031 Operator Details

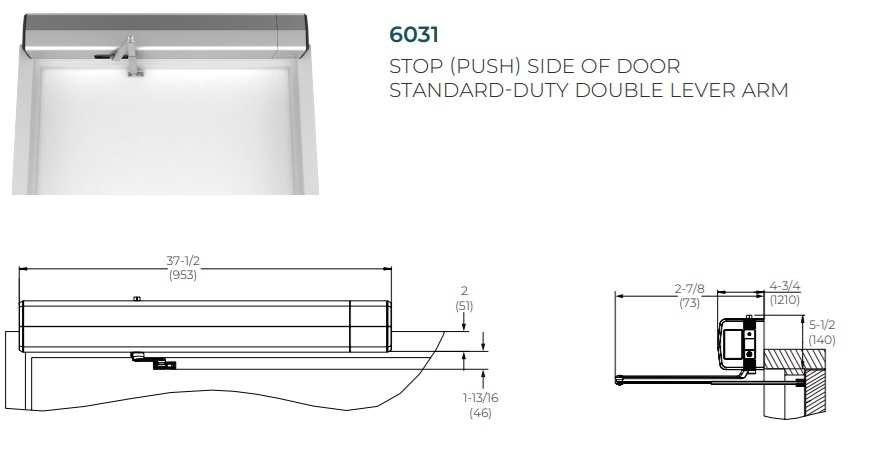

Norton 6061 Operator Details

- Option:Choose Handing (What is handing? Click link here to know more):

- https://blog.locksandsafes.com/2020/07/28/door-hardware-handing-guide/

- Option:Choose Finish (What is this? Click here to see our detailed Door Hardware Finish Guide):

- https://blog.locksandsafes.com/2020/07/28/lock-and-door-hardware-finishes/